Pro Team Collection

Building Fast

This project was one for the true lovers of Road cycling and for our core value, to suffer. The Ultimate in precision and speed together to create the fastest road and racing jerseys in the industry - our new Pro Team Collection Jerseys, Aero and ‘Blaero’-suits.

Design Expression

The visual language for the Pro Team collection were developed through a series collaborative workshop process with the Rapha race team and key brand tastemakers. The objective was to ensure that the collection’s aesthetic and functional DNA authentically reflected the spirit of elite performance and the culture of professional cycling.

Through these sessions, we explored how performance, precision, and minimalism could coexist with bold, modern expression. Insights from athletes shaped decisions around form, proportion, and color application — translating race-day functionality into a cohesive design system that felt unmistakably Pro Team.

The resulting visual identity became more than a look; it served as a design code — integrating athlete feedback, performance needs, and brand integrity into every product detail. This approach ensured that the Pro Team collection stood as a true representation of Rapha’s commitment to purposeful design and performance-led innovation.

This new collection of Jerseys harnesses the future of fast.

Our latest Pro Team collection of jerseys and speedsuits utilises the latest in high quality Italian materials, and highly technical details, construction and features.

Through advanced patterning, new details and materials, we redefined the future of aero, race and training jerseys for our 2024 Pro Team collection.

We tested on our EF Tibco male and female athletes in the wind tunnel and could ensure every step of the process we were listening to our key athletes and ensuring we were making the best jerseys for the peloton.

Design Direction

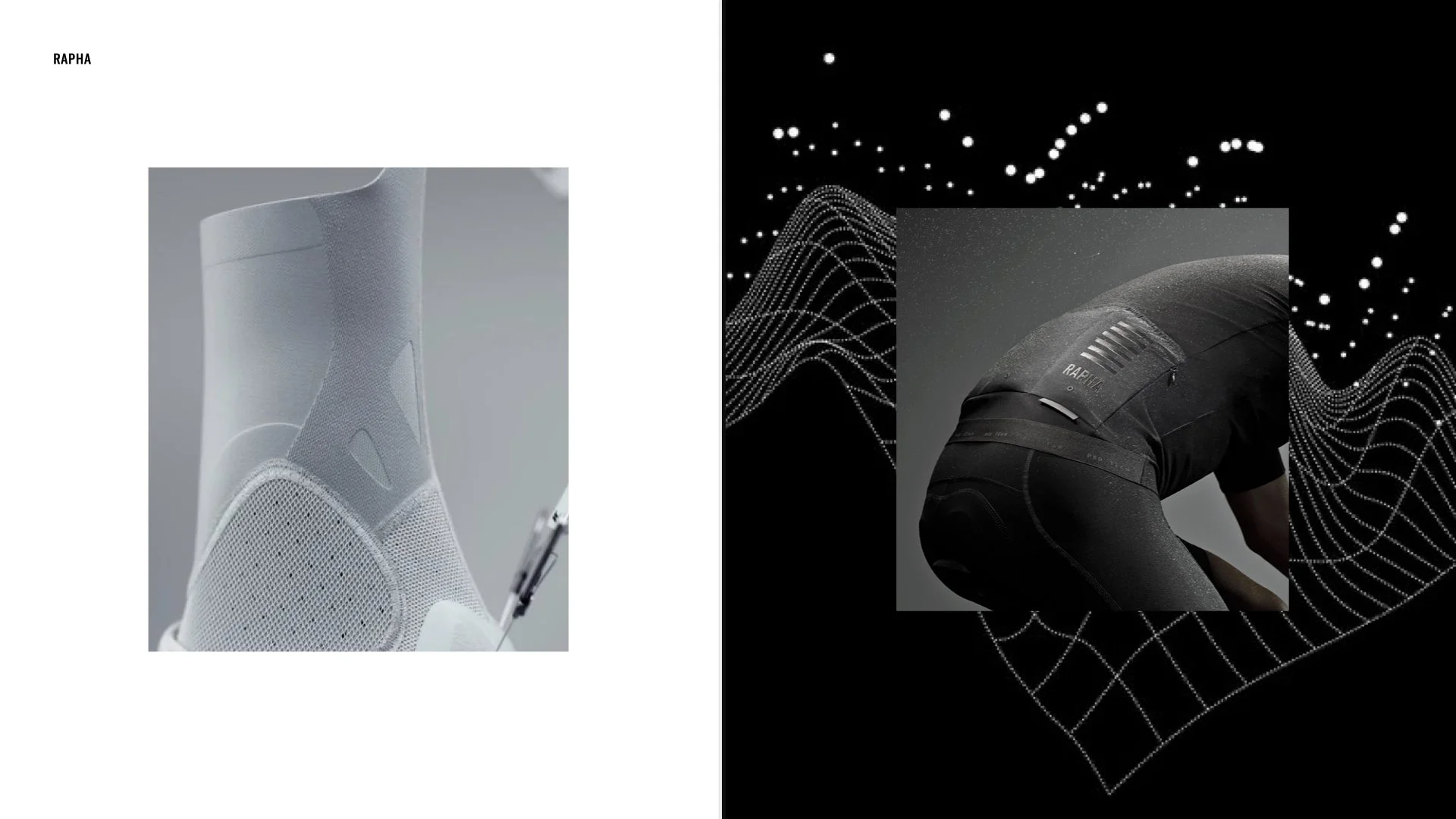

Through an advanced pattern-making process, we analyzed the elongation, recovery, and tensile behavior of each material to map fabric placement with precision across every garment.

Areas requiring greater flexibility — such as the shoulders and upper back — were engineered with high-stretch textiles to support full range of motion, while zones demanding stability and control, like the core and lower back, utilized denser structures to maintain aerodynamic integrity in the riding position.

Lightweight fabrics were strategically positioned to enhance breathability and reduce drag without compromising durability.

The construction approach further elevated each styles design identity. Refined bonding and minimal-seam sewing techniques delivered a smooth, sculpted silhouette that reduced friction and visual noise.

This combination of technical precision and crafted simplicity resulted in products that felt both future-forward and timeless — garments that performed at the highest level while embodying the purity and elegance central to Rapha’s design ethos.

Detailed Fit + Construction

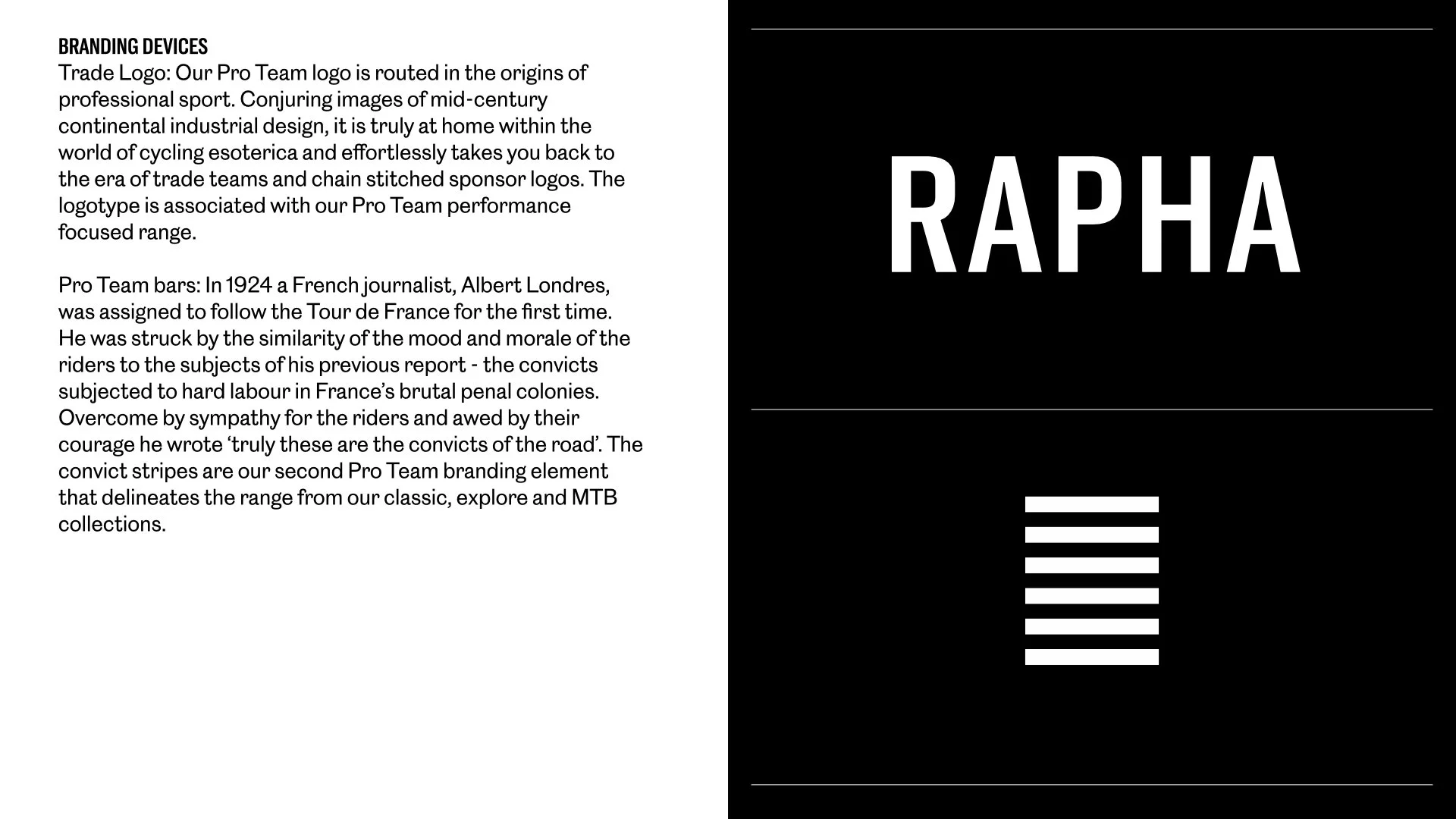

Pro Team Identity

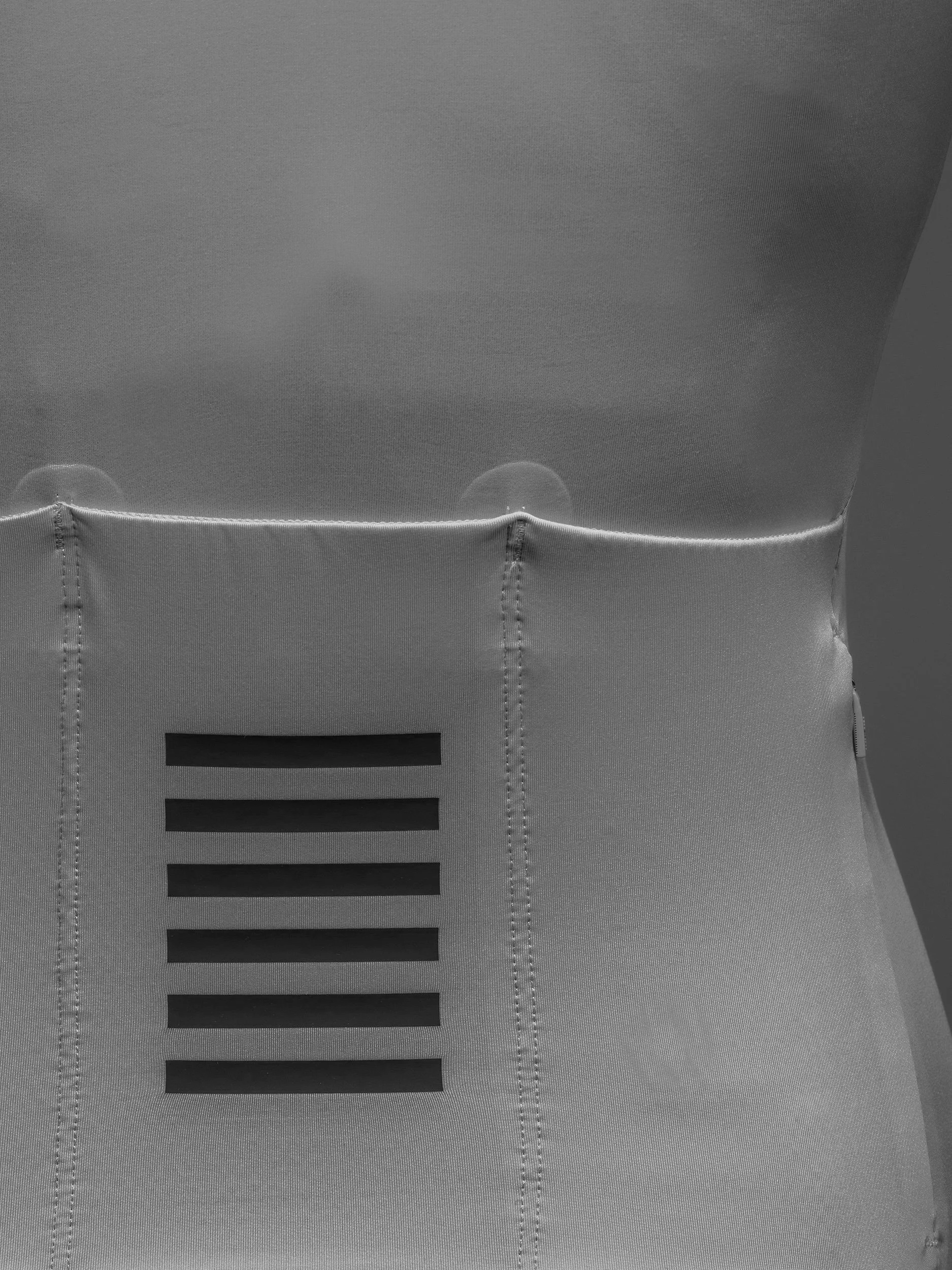

Our Race collection in Pro Team has been founded on the two trademarks defined under the love of racing and the sense of suffering as “convicts of the road”, hence the 6 bars that create the mid point lines on the road as you pass them at speed.

We chose to build a more bold and progressive approach to the convicts and ensured a prominent and larger scale placement on the back of every rider as a reminder to the cyclists behind them who they’re up against.

Our brand is bound by our care to the signature armband on our jerseys, and with using such highly engaged materials, has in the past caused issues in Pro Team with creating unsightly stretching due to the combination of seams through bonding or sewing. We chose to use our Trade Rapha logo as a signifier to the armband placement and for the scale to act as prominent prideful nod to our heritage as a brand. The dynamic placement is for an aggressive on bike position that speaks to the nature of how we expect our products to be worn in an “on-bike” environment.

Aero Jersey: Through using an aerodynamic umbrella structured woven stretch material through the upper shoulder, underarm and sleeve this reduces drag at high output speeds, all tested in wind tunnel testing for validation. The Italian “Clima” material also provides incredible power, to reduce muscle fatigue and that “held in” experience when wearing the garment. It is a super lightweight, high tenacity yarn that has incredible wicking properties and is highly durable when panelled in under tension.

The front body is made with a super breathable and mailable Italian single jersey that is designed to engage with your body under tension. Back pockets and the back panel is a 1-way stretch single jersey knit, providing stability for pockets once they are fully packed for your long durations on the bike , and creates comfort in engagement around the body as it stretches across the broader parts of your body once on bike. This material also has a UPF protection 50+, so is perfect to ride in all day under the sun. It also had a high wicking functionality and an anti-odor protection finish. These combination of materials is what provides the ultimate performance for our elite athletes to excel on bike. With details such as bonded back pockets, a low profile bonded collar for on bike, clean finish hem elastic for holding pockets in place and the ultimate patterning for an aggressive on bike product. All materials are 100% recycled as a focus on providing a sustainable approach to our newly resources fibres.

Our pattern creates the ultimate in experience for an engaged riding experience with the ultimate in comfort underarm and engagement through pockets and feel throughout the body.

In The Details

The use of mesh materials from our expert Italian material mills on our Training, Race and Thermal products utilise a variety of material properties for you to perform at your best.

Each garment is meticulously studied for material paneling properties to fit the purpose of each garment.

Training Jersey: Through using a lightweight mesh in the front panel and sleeves, this texture creates an aerodynamic benefit to the garment. It also provides air permeability for cooling the body under high tempo days and performs incredibly well when it comes to fast drying time and wicking moisture away from the body. The back panel is a 1-way stretch single jersey knit, providing stability for pockets once they are fully packed for your long training rides, and creates comfort in engagement around the body as it stretches across the broader parts of your body once on bike. This material also has a UPF protection 50+, so is perfect to ride in all day under the sun. It also had a high wicking functionality and an anti-odor protection finish. These combinations of materials is what provides such an incredible performance jersey with all the details such as bonded back pockets, a low profile collar for on bike, clean finish hem elastic for holding pockets in place and the ultimate patterning for an aggressive on bike product. All materials are 100% recycled as a focus on providing a sustainable approach to our newly resources fibres.

A continuous feedback loop between the design team and athletes was central to the development process.

At each prototype phase, direct dialogue and on-bike testing sessions informed precise adjustments to fit, mobility, and garment behaviour under race conditions. Every iteration brought new insights — from how the suit adapted to heat and motion, to how hydration weight shifted over time — allowing the team to progressively refine patterning, materials, and construction details to enhance both comfort and performance.

One of the key innovations lay in the re-engineering of the back panel pocket — or “aerostat” — to stabilise a 2L hydration bladder without disrupting the garment’s aerodynamic form.

Prototyping began with extensive athlete wear testing to understand body mechanics, temperature regulation, and fluid dynamics during ultra-endurance efforts.

Early versions of the suit were tested in both controlled environments and real-world scenarios, leading to refinements in pattern placement, ventilation mapping, and on-body weight distribution.

Wind tunnel testing validated measurable aerodynamic gains, ensuring that the integration of a hydration system would not compromise the suit’s drag coefficient or performance profile.

Patterning and internal bonding techniques were refined repeatedly to achieve a balance of support, stretch, and access.

The result allowed for smooth, rapid removal and replacement of the bladder while maintaining airflow integrity and comfort against the rider’s back.

The final Blaerosuit represented the pinnacle of functional design: where engineering precision met the emotional power of purposeful innovation.

It was a product that redefined what an aerosuit could be — future-forward, athlete-driven, and uncompromisingly fast.

The Future of Fast and Long

The Rapha Blaerosuit was developed as a breakthrough in performance design — an evolution of the aerosuit that combined aerodynamic efficiency with endurance functionality. The design team was tasked with creating a suit that could house an internal hydration system for athletes such as Lachlan Morton, enabling them to ride long, heat-intensive races with sustained hydration, reduced fatigue, and fewer water transfer stops.